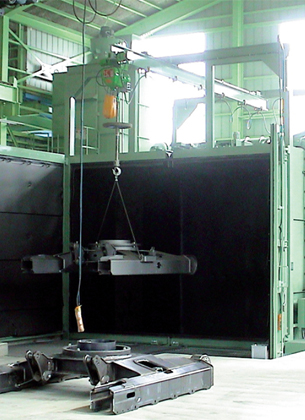

FTF-0P(Tumbler type)

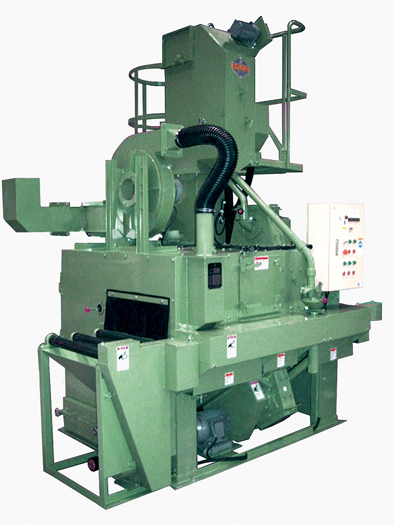

Product explanations

Good for batch operation. Blasting is done while workpieces roll on the rubber-make endless belt. Once blasting is finished, workpieces are unloaded by reverse rotation of the belt. Since the belt of P-model is inclined downward when unloaded, even round and small workpices are completely unloaded. Other than fully automated type (patented), semi-automated type with manual door or manual loading is also avilable. Different models are available for various kinds of workpieces.

Automatic loading/unloading function is available as an option. The P model provides full unloading via descent of the front roller (patented). An integrated dust collector on the back of the machine requires little space. For blasting of products that produce dust, a separate dust collector can be connected.

*Only the NTF-1 type has no integrated dust collector. The high chrome steel lining a standard specification. However, low-priced machines specialized only for zinc shot with a simple lining are also available.

Option: Trommel-type separator, inverter vertical slide door

Tumbling type series

NTSF-153LA,NTB-S,NTF-0,FST-0,NTF-1,TF-77,NTF-100LA,AMTB-25

Product details

- Model

- FTF-0P

- Cabinet size

- W930mm x L1270mm x H2300mm

- Max. weight of product(s)

- 25L

- Max. weight of product(s)

- 60kg

- Dimensions of a barrel

- φ400 x 470L

- Dust collector

- Conbined unit

- Application

- Remove,Scrape,peel

- Application

- Stain finish

- Purpose

- Peeling of painting, Coating paint processing, Roughing of surface, Peening.

Page number : sb50

FTF-0P

※Click here to switch the picture

Related products

We provide variety of machines for your needs. Please do not hesitate asking us.

Page number : sb50